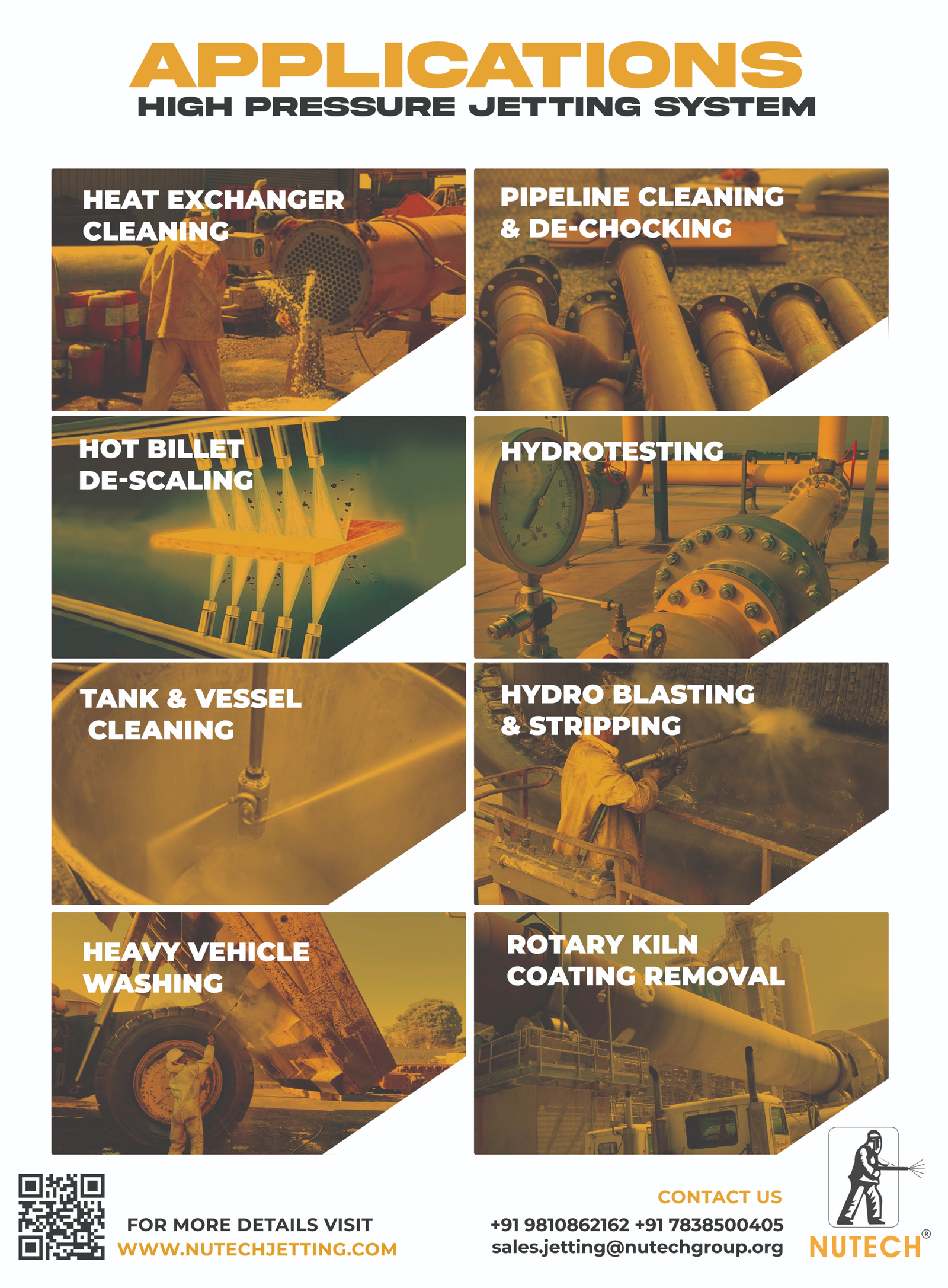

Applications of High Pressure Jetting: The Versatile Cleaning Technology Powering India’s Industries

When it comes to industrial maintenance, one solution doesn’t fit all. But at Nutech Jetting, we believe one high-pressure jetting system can serve many industries — and do it faster, cleaner, and more efficiently.

Our jetting solutions are engineered for tough environments and critical equipment. Whether it’s descaling heat exchangers or stripping stubborn coatings from kilns, precision and pressure are at the core of every job we do.

Here’s how our high-pressure jetting systems are used across industries:

🔹 1. Heat Exchanger & Pipeline Cleaning

Clogged heat exchangers and choked pipelines lead to energy loss and unplanned downtime. Our jetting systems remove scale, sludge, and other deposits without damaging the surface — restoring efficiency and flow instantly.

🔹 2. Hot Billet De-Scaling

In steel and metal processing units, surface scaling can compromise quality. Our jetting system removes oxidized layers from hot billets with speed and consistency, improving finish and performance.

🔹 3. Hydro Blasting, Hydro Testing & Stripping

From cleaning surfaces before repainting to testing the strength of vessels and pipelines, high-pressure hydro-blasting delivers power without chemicals. It’s eco-friendly and precise.

🔹 4. Tank, Vessel & Vehicle Washing

Whether it’s industrial tanks or heavy machinery, our systems clean with pressure — reaching corners manual cleaning can’t. Safe for surfaces, tough on grime.

🔹 5. Rotary Kiln Coating Removal

Removing baked-on coatings from rotary kilns in cement and fertilizer plants is a high-risk, high-skill job. Our automated jetting solutions make it safer, quicker, and residue-free.

🏭 Industries We Serve

Our systems are already trusted by plants across:

-

Thermal & Biomass Power Plants

-

Petrochemical & Refinery Units

-

Steel & Cement Plants

-

Sugar, Paper & Chemical Industries

-

Paint, Fertilizer & Heavy Machinery Manufacturing

💡 Why Choose Nutech Jetting?

✅ Reverse-Engineered Precision

✅ Pressure Ratings Tailored to Application

✅ Reliable After-Sales Support

✅ Fast Deployment & On-Site Servicing

✅ Made in India, Built to Perform

📞 Let’s Power Your Maintenance With Pressure

Whether you’re looking for a turnkey cleaning solution or a custom-built jetting unit, our team is ready to support your plant’s efficiency goals.

📩 Email: sales.jetting@nutechgroup.org

📞 Call: +91 98108 62162 | +91 78385 00405

🌐 Website: www.nutechjetting.com

#NutechJetting #HighPressureJetting #IndustrialCleaning #HydroBlasting #MaintenanceSolutions #PlantEfficiency #MakeInIndia #EngineeringExcellence #PoweringIndustries