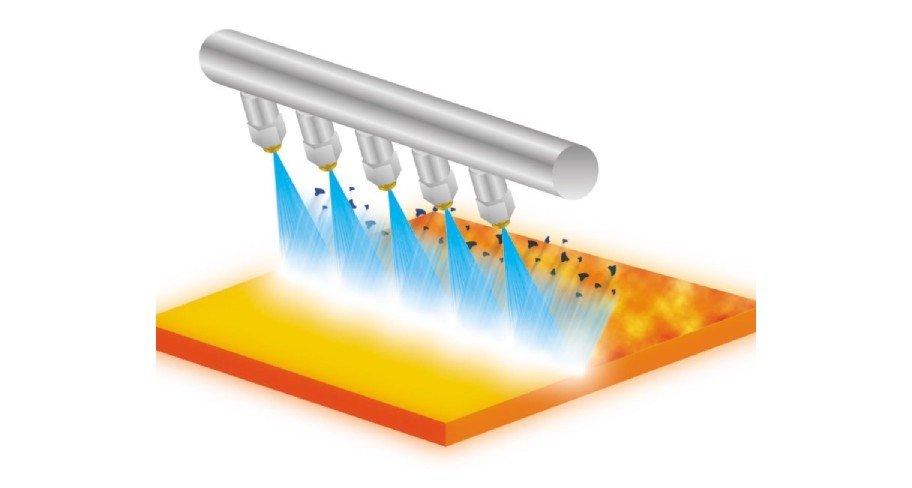

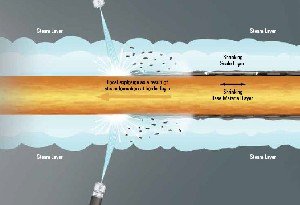

Hot billet descaling is a crucial process in steel manufacturing aimed at removing scale and surface oxides from freshly cast or reheated billets. This operation is essential to ensure the quality of the final product and the efficiency of subsequent processing steps such as rolling and forging. NUTECH Energy Efficient Jetting Equipments, with its superior design and metallurgy outperform other prevailing contemporary pumps in serving this purpose while saving water consumption, power and carbon credit, boosting overall efficiency and productivity of hot steel rolling or forging plant.

Scale Formation:

During casting or reheating processes, steel billets accumulate scale—a layer of oxides that forms on the surface due to exposure to high temperatures and atmospheric conditions.

During casting or reheating processes, steel billets accumulate scale—a layer of oxides that forms on the surface due to exposure to high temperatures and atmospheric conditions.

Impact on Quality:

Scale on billet surfaces can hinder subsequent manufacturing processes, leading to defects in the final product. It disrupts uniform heating and impedes proper material deformation during rolling or forging.

Scale on billet surfaces can hinder subsequent manufacturing processes, leading to defects in the final product. It disrupts uniform heating and impedes proper material deformation during rolling or forging.

Desired Outcome:

Hot billet descaling aims to remove scale and surface oxides, ensuring clean and uniform surfaces for downstream operations. This process is critical for maintaining product quality, dimensional accuracy, and surface finish.

Hot billet descaling aims to remove scale and surface oxides, ensuring clean and uniform surfaces for downstream operations. This process is critical for maintaining product quality, dimensional accuracy, and surface finish.

Applications

Send Inquiry

+91 9810 862 162